AISI/SAE 1018 Carbon Steel Bar

Keywords : SummitSteel

Classification :

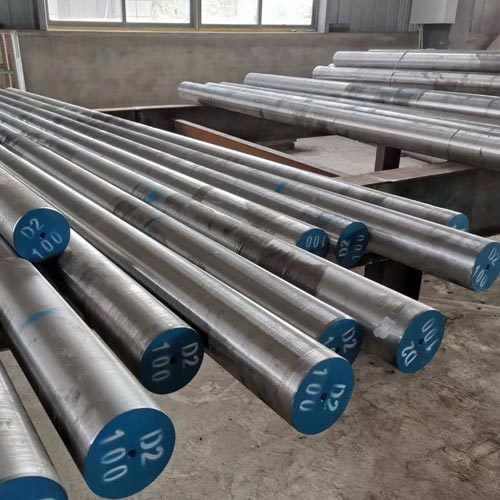

PRODUCT DETAILS

AISI/SAE 1018 Carbon Steel Bar Description

AISI 1018 carbon steel round bars are made of carbon steel, and its composition includes carbon, chromium, manganese, molybdenum, phosphorus, sulfur and silicon. Carbon steel SAE1018 rods are commonly used for shafts, pins, rods, spindles, sprocket assemblies and a wide range of parts. The 1018 bar can be finely processed without any difficulty, and its chips are hard and continuous, so it can be processed into all shapes.

Product Parameters

Product Name | AISI/SAE 1018 Carbon Steel Bar | |||

Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

Common Round Bar Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

Flat Steel Common Specifications | 6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm | |||

Hexagon Bar Common Specifications | AF5.8mm-17mm | |||

Square Bar Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

Length | 1-6meters, Size Accept Custom | |||

Diameter(mm) | Hot Rolling Round Bar | 25-600 | Cold Rolling Square Bar | 6-50.8 |

Hot Rolling Square Bar | 21-54 | Cold Rolling Hexagon Bar | 9.5-65 | |

Cold Rolling Round bar | 6-101.6 | Forged Rebar | 200-1000 | |

Surface Process | Bright, Polished, Black | |||

Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

Chemical Composition

Carbon Steel | C | Fe | Mn | P | S |

1018 | 0.14-0.20% | 98.81-99.26% | 0.60-0.90% | 0.040% | 0.050% |

Mechanical Properties

Tensile Strength | Yield Strength | Elongation % | Hardness(Brinell) | Hardness(Rockwell B) |

440MPa | 370MPa | 22 | 126 | 71 |

Scope of Application

Carburized parts, including worms, gears, pins, pins, tools and non-critical parts of mold sets; tool brackets, pinions, mechanical parts, ratchets, positioning pins and chain pins.

| USA | Japan | Germany | U.K. |

|

France | Italy | Spain | Switzerland | China | |

|

AISI/SAE |

JIS |

W‐nr. |

DIN |

BS |

EN |

AFNOR |

UNI |

UNE |

SS |

GB |

|

A570.36 |

STKM 12A |

1.0038 |

RSt.37‐2 |

4360 |

‐ |

E 24‐2 |

‐ |

‐ |

1311 |

15 |

|

- |

STKM 12C |

- |

- |

40 C |

- |

Ne |

- |

- |

- |

- |

|

1015 |

‐ |

1.0401 |

C15 |

080M15 |

‐ |

CC12 |

C15, C16 |

F.111 |

1350 |

15 |

|

1020 |

‐ |

1.0402 |

C22 |

050A20 |

2C |

CC20 |

C20, C21 |

F.112 |

1450 |

20 |

|

1213 |

SUM22 |

1.0715 |

9SMn28 |

230M07 |

1A |

S250 |

CF9SMn28 |

F.2111 |

1912 |

Y15 |

|

11SMn28 |

||||||||||

|

12L13 |

SUM22L |

1.0718 |

9SMnPb28 |

‐ |

‐ |

S250Pb |

CF9SMnPb28 |

11SMnPb28 |

1914 |

‐ |

|

‐ |

‐ |

1.0722 |

10SPb20 |

‐ |

‐ |

10PbF2 |

CF10Pb20 |

10SPb20 |

‐ |

‐ |

|

1215 |

‐ |

1.0736 |

9SMn36 |

240M07 |

1B |

S300 |

CF9SMn36 |

12SMn35 |

‐ |

Y13 |

|

12L14 |

‐ |

1.0737 |

9SMnPb36 |

‐ |

‐ |

S300PB |

CF9SMnPb36 |

12SMnP35 |

1926 |

‐ |

|

1015 |

S15C |

1.1141 |

Ck15 |

080M15 |

32C |

XC12 |

C16 |

C15K |

1370 |

15 |

|

1025 |

S25C |

1.1158 |

Ck25 |

‐ |

‐ |

‐ |

‐ |

‐ |

‐ |

25 |

|

A572-60 |

‐ |

1.890 |

StE380 |

4360 55 |

‐ |

‐ |

FeE390KG |

‐ |

2145 |

‐ |

|

1035 |

‐ |

1.0501 |

C35 |

060A35 |

‐ |

CC35 |

C35 |

F.113 |

1550 |

35 |

|

1045 |

‐ |

1.0503 |

C45 |

080M46 |

‐ |

CC45 |

C45 |

F.114 |

1650 |

45 |

|

1140 |

‐ |

1.0726 |

35S20 |

212M36 |

8M |

35MF4 |

‐ |

F210G |

1957 |

‐ |

|

1039 |

‐ |

1.1157 |

40Mn4 |

150M36 |

15 |

35M5 |

‐ |

‐ |

‐ |

40Mn |

|

1335 |

SMn438(H) |

1.1167 |

36Mn5 |

‐ |

‐ |

40M5 |

‐ |

36Mn5 |

2120 |

35Mn2 |

|

1330 |

SCMn1 |

1.1170 |

28Mn6 |

150M28 |

14A |

20M5 |

C28Mn |

‐ |

‐ |

30Mn |

|

1035 |

S35C |

1.1183 |

Cf35 |

060A35 |

‐ |

XC38TS |

C36 |

‐ |

1572 |

35Mn |

|

1045 |

S45C |

1.1191 |

Ck45 |

080M46 |

‐ |

XC42 |

C45 |

C45K |

1672 |

Ck45 |

|

1050 |

S50C |

1.1213 |

Cf53 |

060A52 |

‐ |

XC48TS |

C53 |

‐ |

1674 |

50 |

|

1055 |

‐ |

1.0535 |

C55 |

070M55 |

9 |

‐ |

C55 |

‐ |

1655 |

55 |

|

1060 |

‐ |

1.0601 |

C60 |

080A62 |

43D |

CC55 |

C60 |

‐ |

‐ |

60 |

|

1055 |

S55C |

1.1203 |

Ck55 |

070M55 |

‐ |

XC55 |

C50 |

C55K |

‐ |

55 |

|

1060 |

S58C |

1.1221 |

Ck60 |

080A62 |

43D |

XC60 |

C60 |

‐ |

1678 |

60Mn |

|

1095 |

‐ |

1.1274 |

Ck101 |

060A96 |

‐ |

XC100 |

‐ |

F.5117 |

1870 |

‐ |

|

W1 |

SK3 |

1.1545 |

C105W1 |

BW1A |

‐ |

Y105 |

C36KU |

F.5118 |

1880 |

‐ |

|

W210 |

SUP4 |

1.1545 |

C105W1 |

BW2 |

‐ |

Y120 |

C120KU |

F.515 |

2900 |

‐ |

Packing and delivery

We can provide,wooden pallet packaging,Wooden packing,Steel strapping packaging,Plastic packaging and other packaging methods.We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements.We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation

CUSTOMER VISIT

Our factory is equipped with advanced professional production facilities and mature technologies, and has a high-quality professional management and technical talent team. Currently, it holds multiple international standard certifications such as ISO, SGS, API, CE, ABS, etc., ranking among the leading levels in China!

FACTORY WORKSHOP

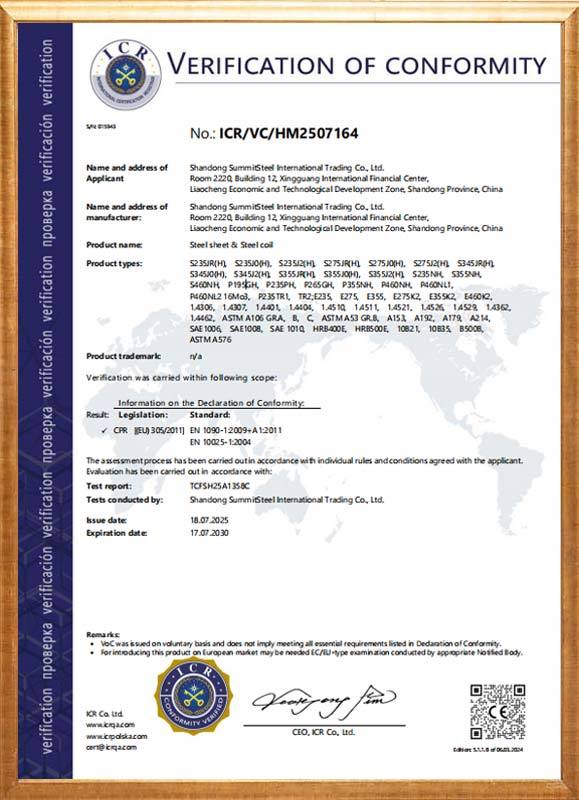

CERTIFICATES

QUALITY MANAGEMENT SYSTEM CERTIFICATION

VERIFICATION OF CONFORMITY

POWER OF ATTORNEY

QUALITY MANAGEMENT SYSTEM CERTIFICATION

CERTIFICATE OF QUALITY MANAGEMENT SYSTEM

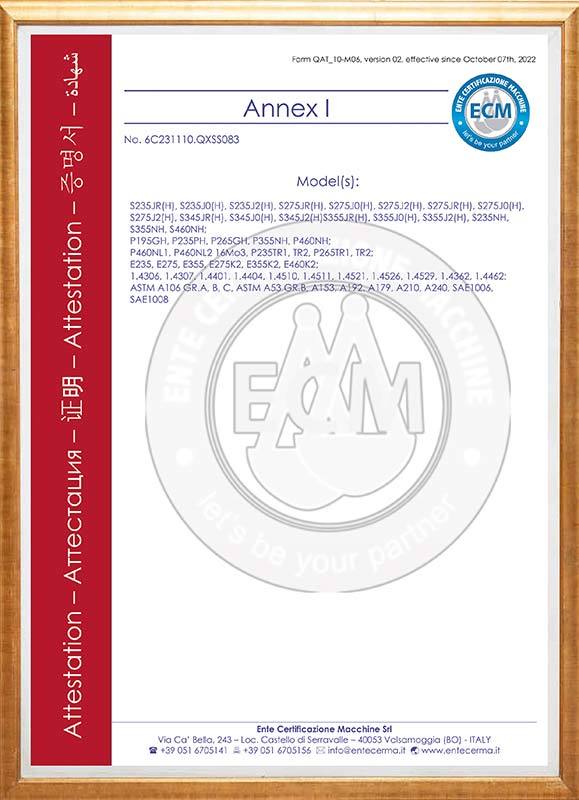

ANNEXL

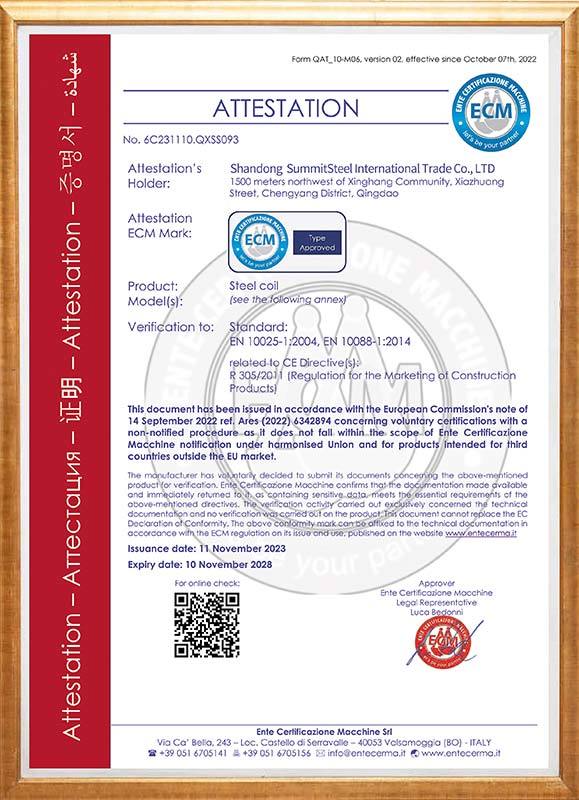

ATTESTATION

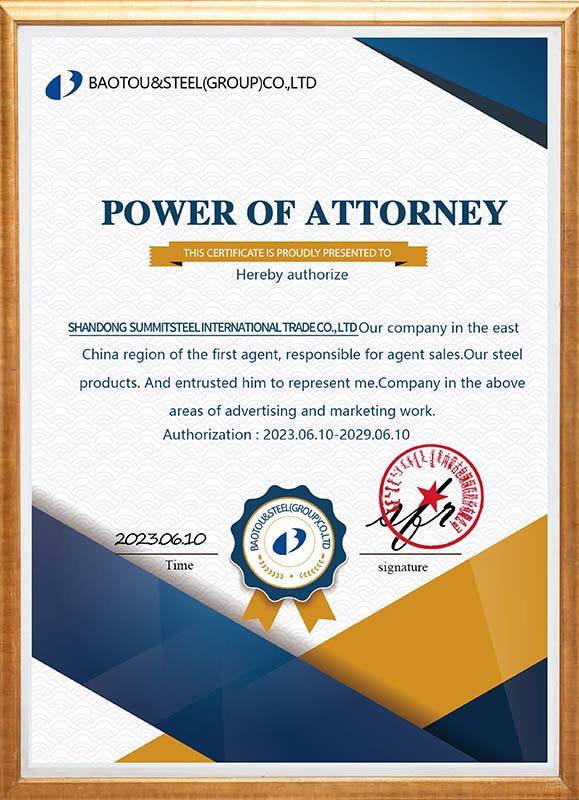

POWER OF ATTORNEY

PARTNERS

APPLICATION FIELD

New Energy

Energy extraction

Precision Manufacturing

Aerospace

FAQ

Q: Can we visit your factory?

Q: How is the quality of your products?

Q: Can I have a sample for testing?

Q: Do you inspect the products before packing?

Q: Can I get your best price?

Q: How to order?

RELATED PRODUCTS

GET A FREE QUOTE